Chips and China

Intel may not be the most obvious place to start when it comes to the China chip sanctions announced by the Biden administration three weeks ago (I covered the ban in the Daily Update here and here); the company recently divested its 3DNAND fab in Dalian, and only maintains two test and assembly sites in Chengdu. Sure, there is an angle about Intel’s future as a foundry and its importance in helping the United States catch up in terms of the most advanced processes currently dominated by Taiwan’s TSMC, but when it comes to exploring the implications and risks of these sanctions I am much more interested in Intel’s past.

Start with the present, though: two weeks ago Intel CEO Pat Gelsinger announced a restructuring of the company, with the goal of putting more distance between its design and manufacturing teams. From the Wall Street Journal:

Intel Corp. plans to create greater decision-making separation between its chip designers and chip-making factories as part of Chief Executive Pat Gelsinger’s bid to revamp the company and boost returns. The new structure, which Mr. Gelsinger disclosed in a letter to staff on Tuesday, is designed to let Intel’s network of factories operate like a contract chip-making operation, taking orders from both Intel engineers and external chip companies on an equal footing. Intel has historically used its factories almost exclusively to make its own chips, something Mr. Gelsinger changed when he launched a contract chip-making arm last year.

Back in 2018 I wrote about Intel and the Danger of Integration:

It is perhaps simpler to say that Intel, like Microsoft, has been disrupted. The company’s integrated model resulted in incredible margins for years, and every time there was the possibility of a change in approach Intel’s executives chose to keep those margins. In fact, Intel has followed the script of the disrupted even more than Microsoft: while the decline of the PC finally led to The End of Windows, Intel has spent the last several years propping up its earnings by focusing more and more on the high-end, selling Xeon processors to cloud providers. That approach was certainly good for quarterly earnings, but it meant the company was only deepening the hole it was in with regards to basically everything else. And now, most distressingly of all, the company looks to be on the verge of losing its performance advantage even in high-end applications.

That article was primarily about Intel’s reliance on high margin integrated processors and its unwillingness/inability to become a foundry serving 3rd-party customers, and how smartphones provided the volume for modular players like TSMC to threaten Intel’s manufacturing dominance. However, it’s worth diving into the implications of Intel’s integrated approach relative to TSMC’s modular approach, because it offers lessons for the long road facing China when it comes to building its own semiconductor industry, highlights why the U.S. is itself vulnerable in semiconductors, and explains why the risk for Taiwan has increased significantly.

TSMC’s Depreciation

Fabs are incredibly expensive to build, while chips are extremely cheap; to put it in economic terms, fabs entail massive fixed costs, while chips have minimal marginal costs. This dynamic is very similar to software, which is why venture capital rose up to support chip companies like Intel, and then seamlessly transitioned to supporting software (Silicon Valley, which is today known for software, is literally named for the material used for chips).

One way to manage these costs is to build a fab once and then run it for as long as possible. TSMC’s Fab 2, for example, the company’s sole 150-millimeter wafer facility, was built in 1990, and is still in operation today. That is one of seven TSMC fabs that are over 20 years old, amongst the company’s 26 total (several more are under construction, including the one in Arizona). The chips in these fabs don’t sell for much, but that’s ok because the fabs are completely depreciated: almost all of the revenue is pure profit.

This may seem like the obvious strategy, but it’s a very path dependent one: TSMC was unique precisely because they didn’t design their own chips. I explained the company’s origin story in Chips and Geopolitics…

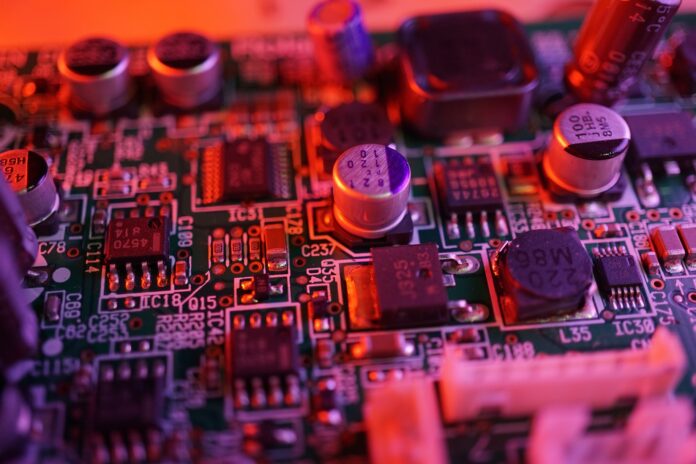

Image by Andra Medium from Pixabay